Air separation unit supporting booster turbine expansion unit

Classification:Boosting Turbine Expander

The company has an advanced and complete process for the design and manufacturing of expansion machines. The scientific design concept

Product Consulting

Product Details

The company has 21 years of experience in the design and production of turbine expansion units, capable of providing the most reasonable and economical system solutions for users based on on-site adjustments.

Largest natural gas processing unit: 1 million cubic meters per day

Largest natural gas liquefaction: 300,000 cubic meters per day

Largest oxygen and nitrogen liquefaction: 288,000 cubic meters per day

Largest internal compression air separation: 80,000 Nm3/h

Largest external compression air separation: 60,000 Nm3/h

key word:Air separation unit supporting booster turbine expansion unit

Related Products

Product Center

Boosting Turbine Expander

Wind mechanism braking turbine expander

Power generation turbine expander

Oil brake turbine expander

accessories

-

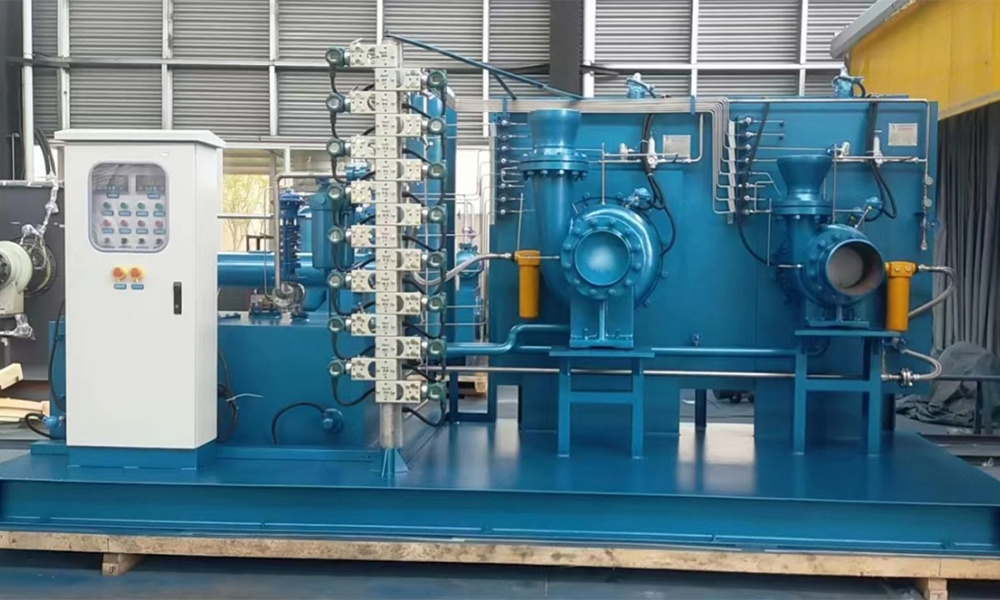

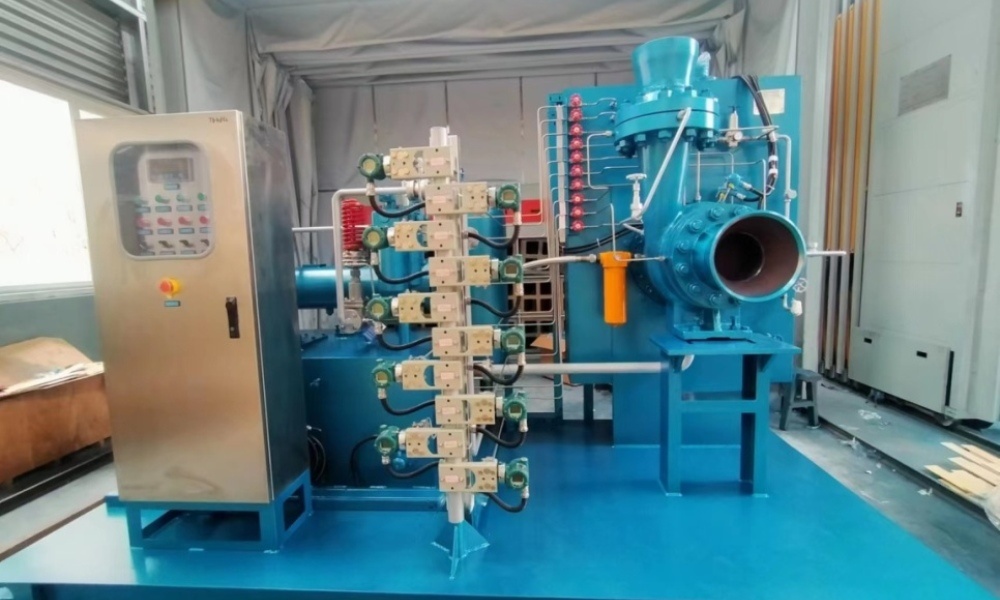

Two host machines and a skid-mounted structure for the oil station - with a junction box control cabinet.

-

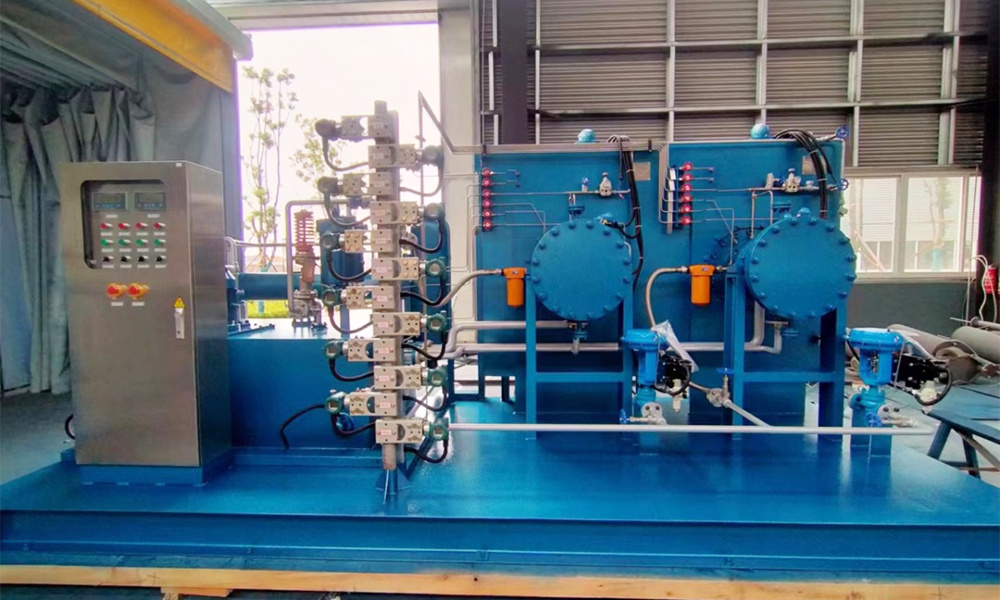

Two host machines and a skid-mounted structure for the oil station - without a junction box control cabinet.

-

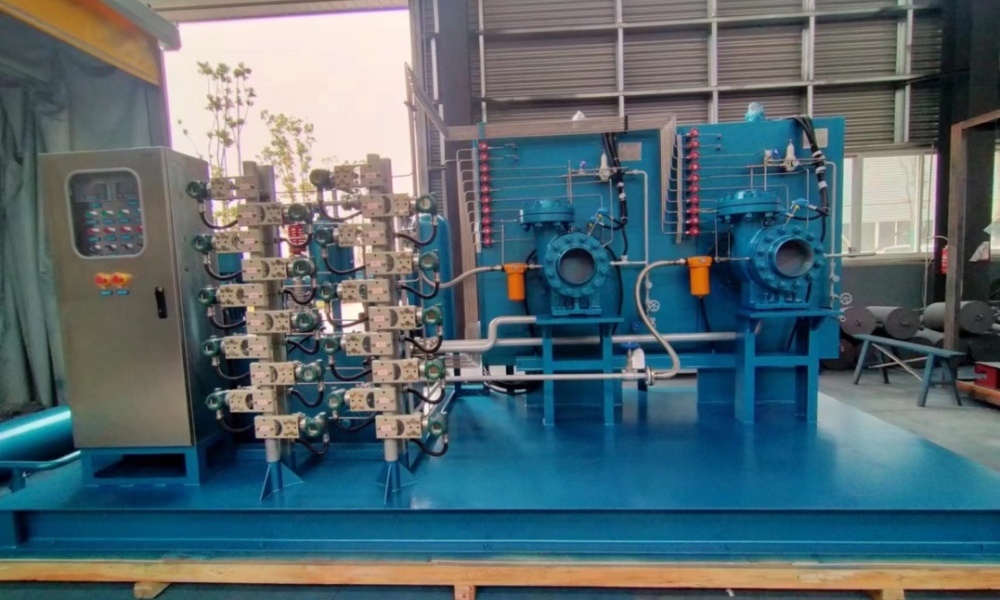

Single host and oil station skid-mounted structure - with junction box control cabinet.

Processing equipment

-

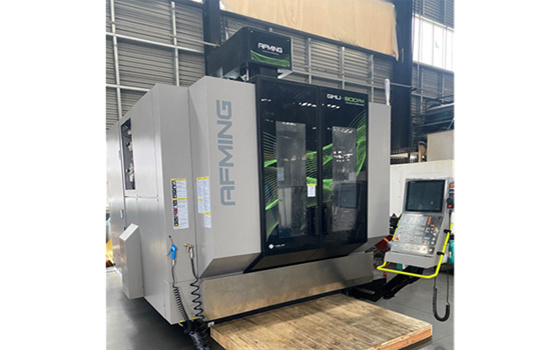

Five-axis machining center

-

Four-axis CNC vertical machining center

-

CNC Vertical Lathe

-

Horizontal CNC Lathe

-

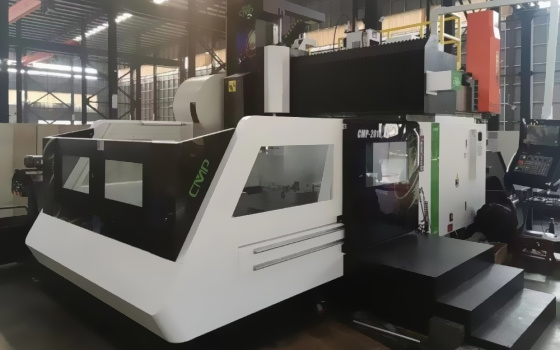

CNC Gantry Machining Center

-

CNC Turning Center

-

CNC lathe

-

In-house Testing System

-

Impeller Brazing Chamber

-

CNC wire cutting machine

-

High-precision dynamic balancing machine

-

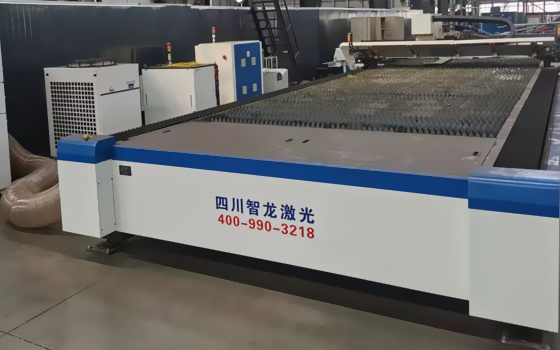

Fiber Laser Cutting Machine

-

Conical Plate Rolling Machine

-

CNC pipe bending machine

Product Consulting

Leave the information you want to consult, we will contact you as soon as possible